TPS tools help us in achieving Toyota

Kaizen:

Kai- Change

Zen- Good

So Kaizen means

change for good. Any improvement (small or big) done to eliminate waste is

called Kaizen.

Kaizen is not innovation; the following table from one of

the earlier Japanese text books (1986) helps me in validating my statement.

Reducing any of the listed below 7 types of Muda (Waste) is called kaizen.

As mentioned earlier, Overproduction is the biggest muda and it leads to all other muda’s (as you read in the example of Curious case of vegetable seller) and so it should be attacked first.

Genchi Genbutsu:

This is always associated with 3G:

1) Gemba:

Actual place.

2) Genbutsu:

Actual thing.

3) Genjitsu:

Actual situation.

Same applies to the Engineers or Managers who sit in office

and try to analyze causes for the problems in the shop floor.

Genchi Genbutsu means ‘Go and See’ at the actual place

(Gemba) to truly understand the actual thing in the actual situation.

1. When

a problem arises, go to the actual place; observe the actual thing at the

actual

time (Situation).

2. Identify

the problem.

3. Take

temporary or counter measure on the spot.

4. Find

the root cause and take a permanent measure.

5. Standardize

the solution to prevent recurrence of the problem.

Management by walking

around in HP:

•

In the early days of Hewlett-Packard (H-P), Dave

Packard and Bill Hewlett devised an active management style that they called Management by Walking around (MBWA).

Senior H-P managers were seldom at their desks. They spent most of their days

visiting employees, customers, and suppliers. This direct contact with key

people provided them with a solid grounding from which viable strategies could

be crafted.

• Going to the source is not limited to only production but to

any field of work. Once we start observing the process, we must build a habit

of questioning ourselves again and again. Preferably Why Why Why? Till we get a

solution/root cause to our problem. These problems are golden eggs. Why’s are

not limited to just 5 times. That’s a myth. Sometimes we might get the solution

at 2nd time or 20th time of asking ‘why’. 5 why is the

name of a technique and not limited to just 5 why’s! It’s a thumb rule to ask

why a minimum of 5 times to go to the root of the problem.

Most of the times, this analysis leads to the Method we are following and need to

improve that.

Let’s take a simple example to understand this theory.

Bulb is not switching on

Why?

There is no power supply to the bulb.

Why?

The fuse is not working.

Why?

There is no power supply to the fuse.

Why?

There is no power supply in the wire.

Why?

The socket is damaged.

Why?

The plug was not put correctly.

So the root cause here is plug was not put correctly and

hence the socket was damaged. The socket should be replaced and care must be

taken while inserting the plug.

As you can observe in this analysis, instead of replacing

the socket, if the bulb or fuse was replaced, then the problem would have not

been solved. Taking a wrong countermeasure is not only a waste of time and money but also

might cause more problems.

Another key point to remember here is the verification of

the 5 why. 5 why can be verified if it satisfies the therefore condition. Let’s verify my root cause.

The plug was not put correctly therefore the socket was damaged, therefore there was no power supply in the wire, therefore there was no power supply to

the fuse, therefore the fuse was not

working, therefore there is no power

supply to the bulb, therefore the

bulb is not switching on.

If it doesn’t satisfy this condition, then there is a

mistake in the analysis.

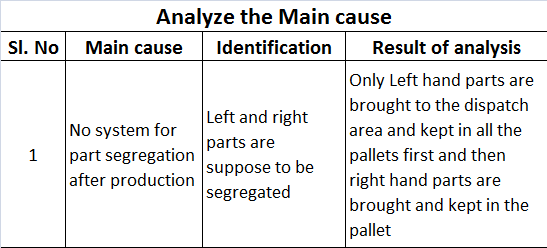

I will give one of the 5 why analysis done by me to

eliminate wrong part supply to customer.

Please do the therefore analysis and give feedback to me .

This completes the Toyota way module.